The Role Of Viscosity Modifier In Improving Product Performance

How do manufacturers ensure that products such as lubricants, paints, and cosmetics maintain the right consistency and flow? One key factor is the use of viscosity modifiers. These additives adjust the thickness and flow properties of liquids, ensuring stability and performance under different conditions.

Adjusting flow properties:

A viscosity modifier controls how a substance flows, making it easier to handle and apply. In motor oils, for example, these additives help maintain an optimal consistency, ensuring proper lubrication across a wide range of temperatures. Without viscosity modifiers, products might become too thick in cold conditions or too thin in high temperatures, leading to reduced performance.

Improving stability:

Many products require a consistent texture to function effectively over time. Viscosity modifiers prevent separation and settling, keeping ingredients evenly distributed. This is essential in products such as paints, adhesives, and personal care items, where uniformity affects quality and effectiveness.

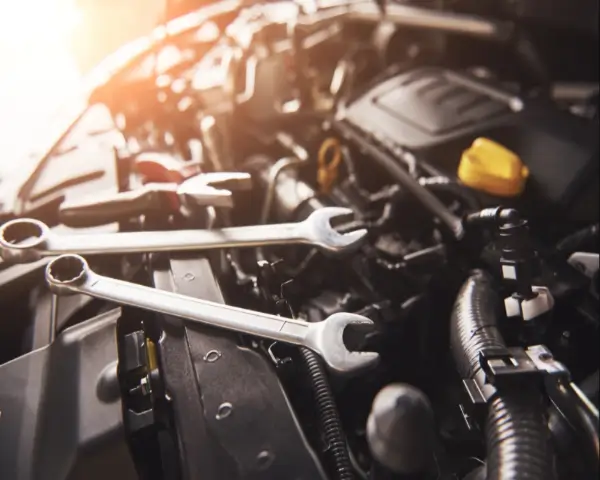

Improving efficiency in lubrication:

In the automotive and industrial sectors, lubricants must provide reliable performance under varying conditions. Viscosity modifiers help oils maintain their protective properties, reducing wear and friction in engines and machinery.

Supporting better application in coatings and paints:

Paints and coatings need the right viscosity to ensure smooth application and proper coverage. If a product is too thin, it may drip or spread unevenly; if too thick, it may not spread well. Viscosity modifiers help maintain the ideal consistency, improving application quality and final appearance.

Improving product experience in cosmetics:

In cosmetics and personal care products, viscosity modifiers create desirable textures and improve ease of use. From lotions to shampoos, these additives ensure that products have a pleasant feel while maintaining stability. They also contribute to the performance of makeup, creams, and gels by preventing separation and ensuring even application.

Adapting to environmental conditions:

Many industries require products that perform consistently despite temperature changes. Viscosity modifiers help materials remain stable in extreme heat or cold, ensuring reliable performance. This is especially valuable in automotive fluids, hydraulic systems, and industrial applications where temperature variations can impact functionality.

Viscosity modifiers play an essential part in improving the performance and stability of various products. By controlling thickness, improving stability, and adapting to environmental conditions, these additives contribute to the effectiveness of lubricants, coatings, cosmetics, and many other applications.